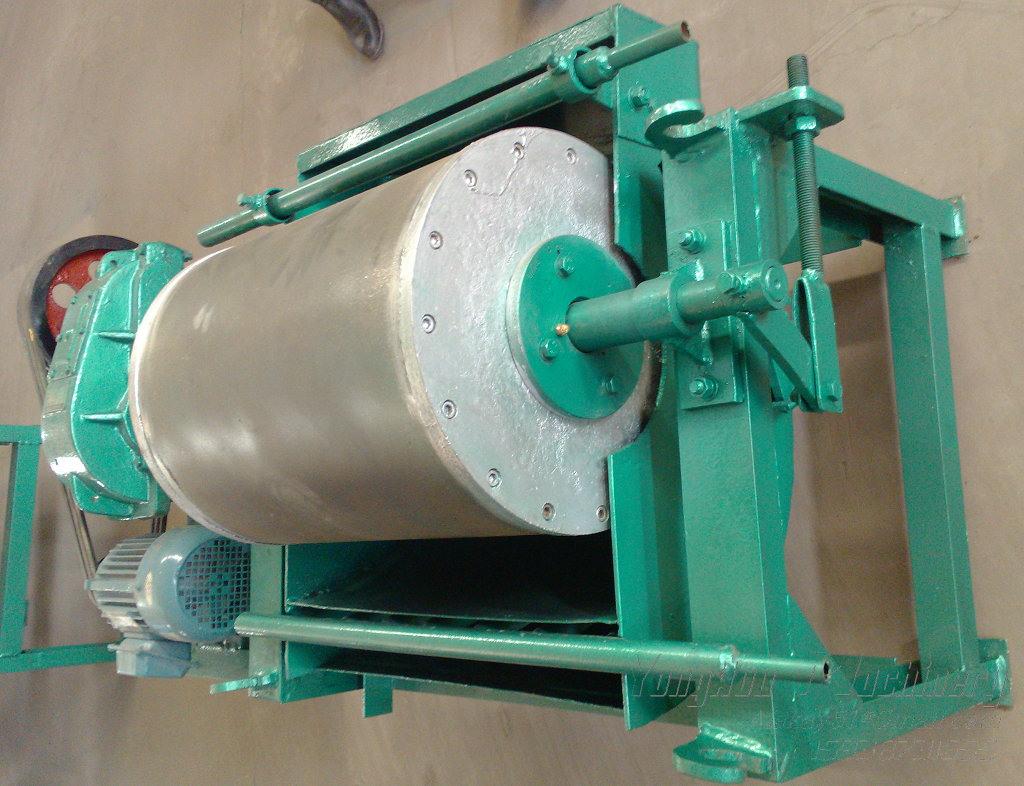

Magnetic Separator

- Feed Size: 0-10mm

- Capacity: 1-180t/h

- Raw materials: chemical materials, grain and oil machinery, abrasives, ceramics, metallurgy, cement, powder metallurgy, rubber, minerals and other materials.

- Application: used in mineral processing, coal washing and chemical industry,

Magnetic Separator is widely used in mineral processing, coal washing and chemical industry, for sorting the wet particle size of 6-10mm. The strong magnetic minerals and magnetic minerals are including two kinds of material: non-magnetic material and magnetic material. Magnetic separator is suitable removing the iron in the coal, non-metal and construction industries.

Advantage of Magnetic Separator

1) High magnet intensity;

2) Low energy consumption;

3) High efficiency;

4) Simple structure;

5) Reliable operation and convenient maintenance

Magnetic Separator Working Principle:

The mineral slurry flows into the cell through box feeder, the mineral particle is loose under the function of water flow of feeder water pipe when they flow into the cell. Affected by magnetic field, the magnetic particle swarm together and form magnetic cluster or chain. With the magnetism of mineral slurry, the magnetic cluster or chain moves toward the magnetic pole, and is absorbed to the cylinder. Because of the polarity of magnetic pole, the revolving directions alternate constantly, and remain fixed when it is working. When the magnetic cluster and chain go round and round along with the cylinder, the mingled gangue and other non-magnetic ore fall down due to the mixing phenomena produced by alternation of magnetic poles, and it is concentrate that is absorbed to the cylinder surface. The concentrate moves to the end of magnetic system where the magnetism is weakest along with the revolving cylinder, and is discharged into concentrate tank by the current ejected by the discharging-ore pipe. The non-magnetic or weak magnetic remained are discharged along with the mineral slurry, and they are gangue.

|

Type

|

Tube diameter (mm)

|

Tube length(mm)

|

Speed

r/min

|

Feeding Size

(mm)

|

Capability

t/h

|

Power

Kw

|

|

CTB6012

|

600

|

1200

|

<35

|

2-0

|

10-20

|

1.5

|

|

CTB6018

|

600

|

1800

|

<35

|

2-0

|

15-30

|

2.2

|

|

CTB7518

|

750

|

1800

|

<35

|

2-0

|

20-45

|

2.2

|

|

CTB9018

|

900

|

1800

|

<35

|

3-0

|

40-60

|

3

|

|

CTB9021

|

900

|

2100

|

<35

|

3-0

|

45-60

|

3

|

|

CTB9024

|

900

|

2400

|

<28

|

3-0

|

45-70

|

4

|

|

CTB1018

|

1050

|

1800

|

<20

|

3-0

|

50-75

|

5.5

|

|

CTB1021

|

1050

|

2100

|

<20

|

3-0

|

50-100

|

5.5

|

|

CTB1024

|

1050

|

2400

|

<20

|

3-0

|

60-120

|

5.5

|

|

CTB1218

|

1200

|

1800

|

<18

|

3-0

|

80-140

|

5.5

|

|

CTB1224

|

1200

|

2400

|

<18

|

3-0

|

85-180

|

7.5

|

|

CTB1230

|

1200

|

3000

|

<18

|

3-0

|

100-180

|

7.5

|

There are some other products you may be intersted in , please click to know about the details.

Carbonization furnace Shisha charcoal briquette machinery Charcoal/coal briquette machine Briquette Machine Hydraulic Briquette Machine Pellet Briquette Machine Sawdust Briquette Machine Rotary DryerINQUIRY

Send your message to us. We'll respond as soom as possible.

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

(※ Click this button to inquiry)

(※ Click this button to inquiry)