-

Jaw Crusher is the main crushing equipment. Jaw Crusher appeared in 1858. Jaw crusher widely used in mining, smelting, building material, highway, railway, water conservancy and chemical industry and many other sectors, broken less than 320 MPa compressive strength of various materials.

-

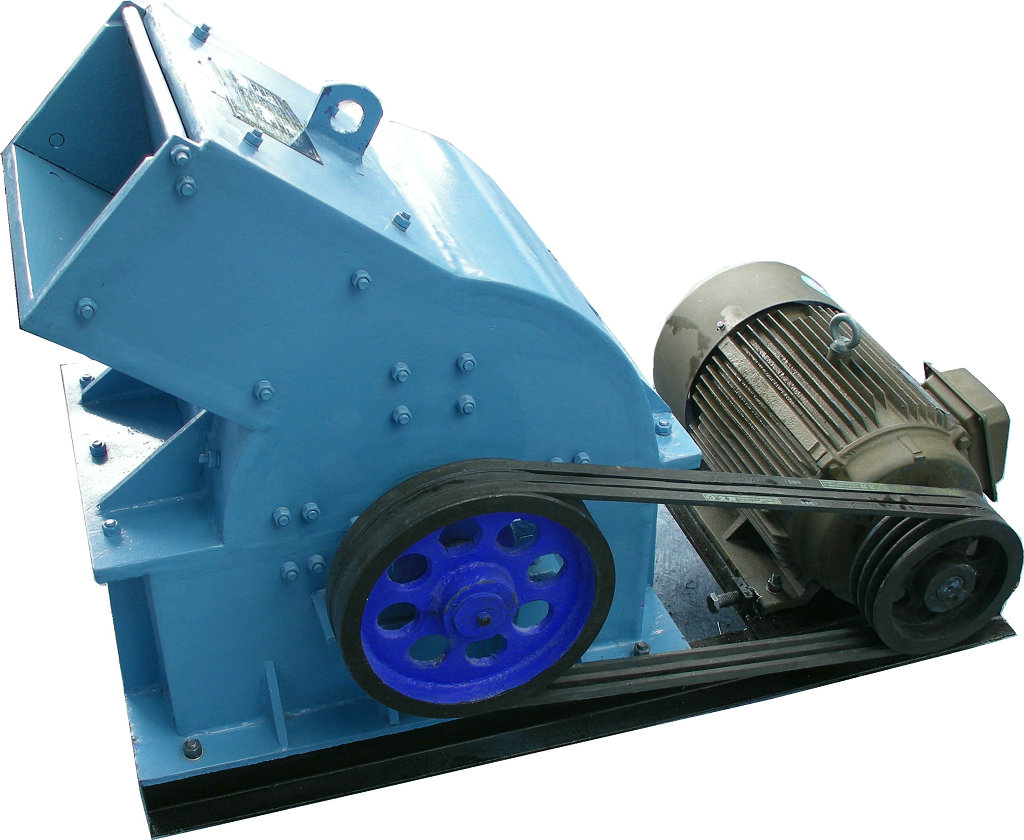

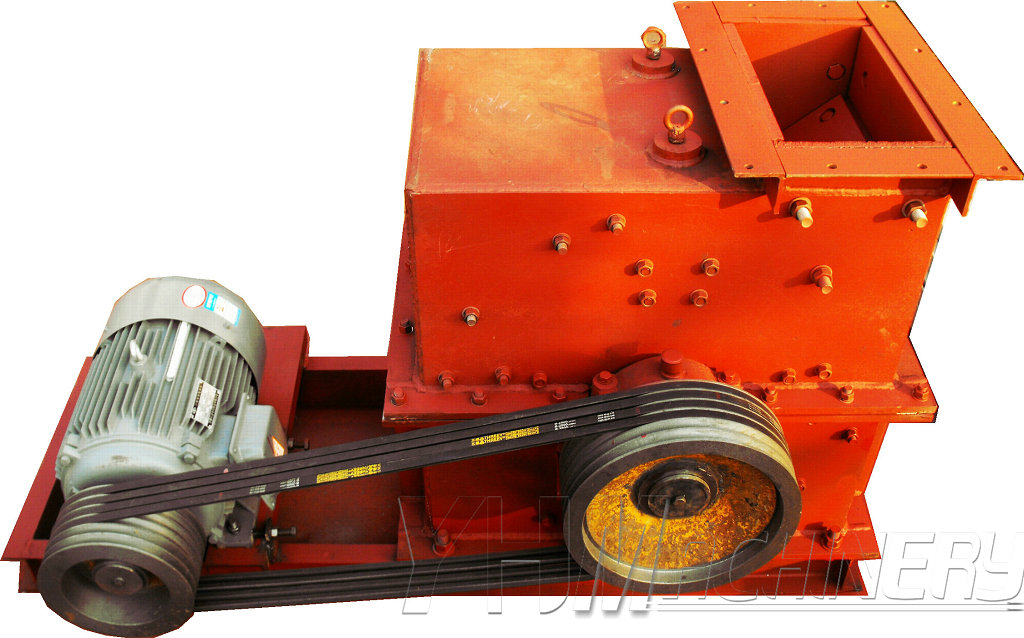

Hammer Crusher usually applied to primary and secondary crushing of different types of material in almost all industrial sectors. Hammer Crusher are suitable for crushing of medium hardness and brittle materials such as limestone, coal, salt, white Asian, gypsum, alum, brick, tile, coal gangue and etc. Hammer crusher can break the material which compressive strength not more than 150 Mpa, humidity less than 15%.

-

Impact Crusher can be used for intermediate and fine crushing in the second and third grade, and can process materials side length less than 100-500 mm, compression crushing strong up to 350 MPa.

-

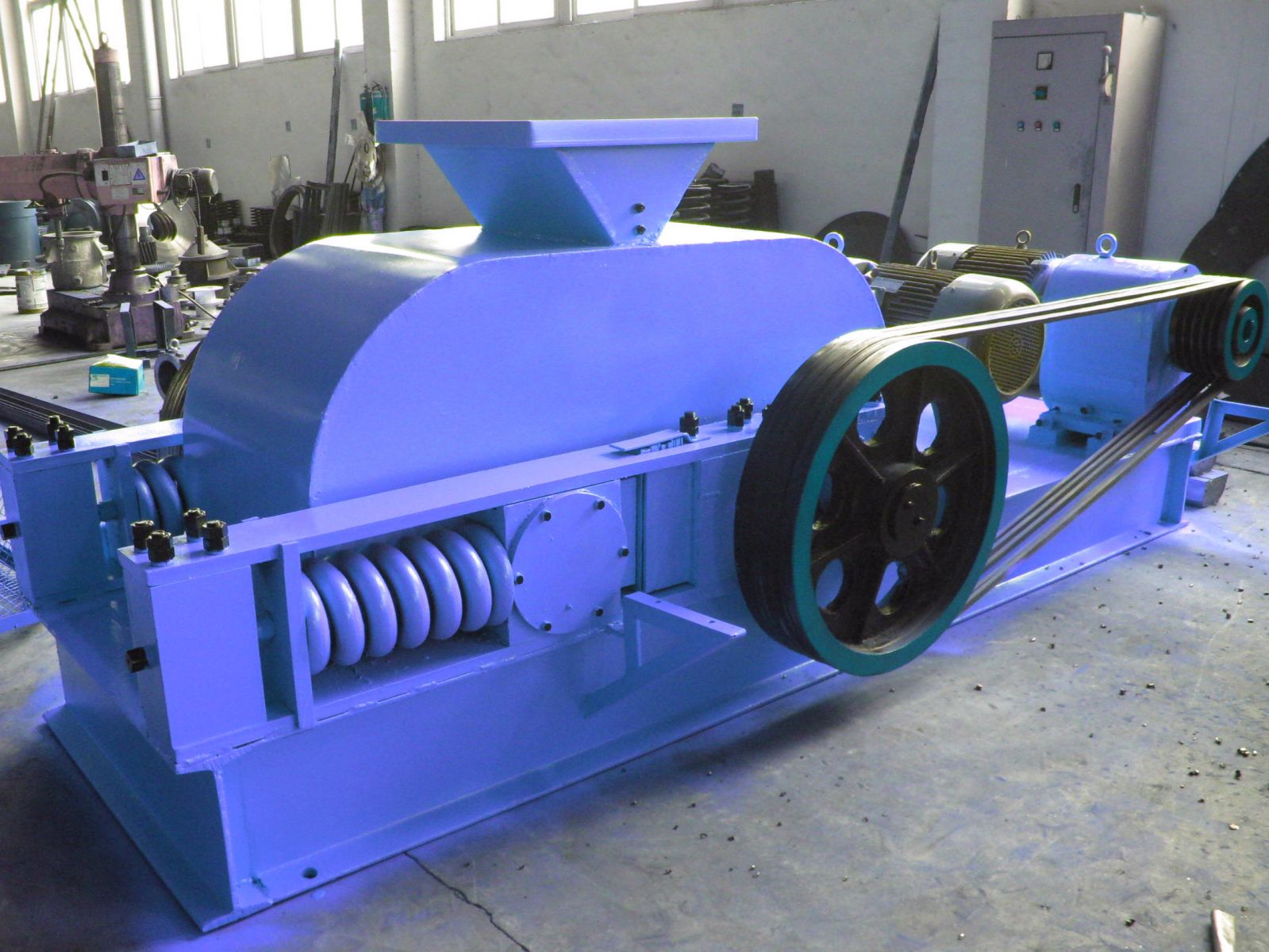

Roll Crusher is suitable for crushing materials of medium hardness cement, metallurgy, chemicals, electricity, coal and other industrial sectors, such as medium and fine crushing operations of limestone, slag, coke, coal and other materials.

-

Vertical Shaft Hammer Crusher especially suited for coal, rock material shaping and manufacturing high proportion machine-made sand, and widely used in fine crushing of rock, cobblestone and other materials. The compressive strength of it cans not more than 140 MPa, humidity less than 15%.

-

Impact Hammer Crusher can handle the side length of not more than 500mm, and compressive strength of less than 350MPa variety of coarse and fine materials (granite, limestone, and concrete), widely used in utilities, highway, artificial aggregates, broken industry. It takes the advantages of the hammer crusher and Impact crusher.

-

Hammer Fine Crusher comes with many years production experience of the crusher, and the advantages of hammer crusher and impact crusher. It is widely used for crushing coal, salt, white Asia, gypsum, alum, brick, tile, limestone and cement clinker, the compressive strength of materials no more than 100 MPa, not more than 15 percent humidity , the expected size (≤ 5 mm 80%)

-

The ring hammer crusher is used for crushing moderately hard and fragile materials in the mining, cement, coal, metallurgy, building materials, and road industries, etc.

-

Cone crusher consist of frame, transmission device, hollow eccentric shaft, bowl-shaped bearing, crushing cone, springs and hydraulic pressure station for adjusting discharge opening. Cone crusher is widely applied in metallurgical, construction, road building and chemical and phosphates industry. This Crusher is configured with Spring-Loaded release system, which allows any inscrutable material to pass through the crusher, without causing damage to the crusher.

-

Vertical Impact Crusher is also named Sand Making Machine; it plays an irreplaceable role in the mine’s fine crushing and most commonly used in the project of sand making in building mechanical.

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

.jpg)

.jpg)

.jpg)

.jpg)