Rotary Kiln

- Feed Size: 0-500mm

- Capacity: 1-150t/h

- Raw materials: Cement, Lime, Refractories, Metakaolin,Titanium dioxide, Alumina, Vermiculite,Iron ore pellets

- Application: Cement plant, Smelter plant, Garbage disposal plants

Rotary kiln is a device used to raise materials to a high temperature (calcination) in a continuous process. Materials produced using rotary kilns include: Cement, Lime, Refractories, Metakaolin,Titanium dioxide, Alumina, Vermiculite,Iron ore pellets.

it is also used for roasting a wide variety of sulfide ores prior to metal extraction. In addition, in the aspects of environmental protection, it has 20 years of history that developed countries use rotary kiln burning hazardous waste, garbage. This not only makes waste minimization, harmless, and will use waste as a fuel that saving of pulverized coal to achieve the purpose of rational utilization of the waste.

Advantages of the Rotary Kiln

1. Dongxing rotary kiln system is used in the most advanced hydraulic gear wheel device, the metering piston pump of high precision, the high precision control valve and contact graphite block sealing devices and other advanced technologies.

2. The drying machine features in easy to operate and operational safety. Compared with the same specification equipment, the rotary kiln stabilizes the thermal system program and improves the equipment operation rate, with the operation rate increased by 10%, the yield increased by 5% -10% and heat consumption reduced by 15%.

Woring Prciple of Rotary Kiln

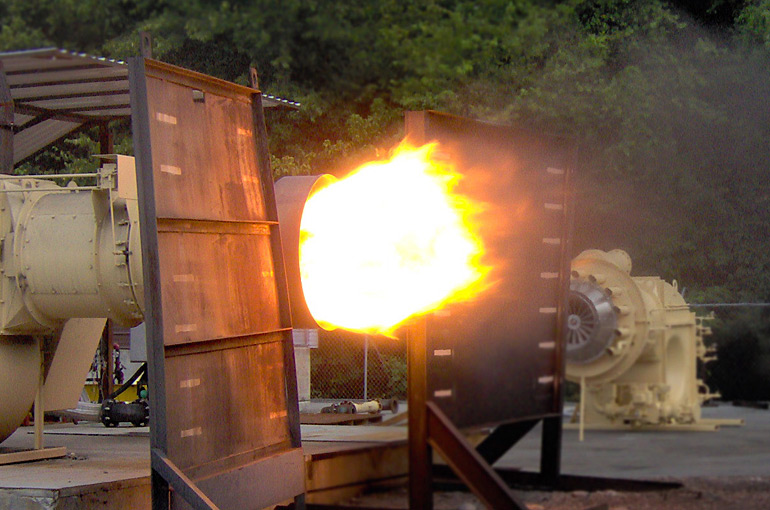

The kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. The material to be processed is fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down towards the lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln, sometimes in the same direction as the process material (co-current), but usually in the opposite direction (counter-current). The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burner-pipe (or "firing pipe") which acts like a large bunsen burner. The fuel we use for this is gas, or pulverized coal.

Mian Rotary Kiln Technical Parameter

(m) Size (m) Capability (t/h) Speed (r/min) Power (kw) Weight (t) φ1.4×33 1.4 33 3 0.9-1.3 0.39-3.96 18.5 47.5 φ1.6×36 1.6 36 4 1.2-1.9 0.26-2.63 22 52 φ1.8×45 1.8 45 4 1.9-2.4 0.16-1.62 30 78.2 φ1.9×39 1.9 39 4 1.65-3 0.29-2.93 30 77.59 φ2.0×40 2 40 3 2.5-4 0.23-2.26 37 119.1 φ2.2×45 2.2 45 3.5 3.4-5.4 0.21-2.44 45 128.3 φ2.5×40 2.5 40 3.5 9.0-10.5 0.44-2.44 55 149.61 φ2.5×50 2.5 50 3 6.25-7.4 0.62-1.86 55 187.37 φ2.5×54 2.5 54 3.5 6.9-8.5 0.48-1.45 55 196.29 φ2.7×42 2.7 42 3.5 10.0-11.0 0.10-1.52 55 198.5 φ2.8×44 2.8 44 3.5 12.5-13.5 0.437-2.18 55 201.58 φ3.0×45 3 45 3.5 12.8-14.5 0.5-2.47 75 210.94 φ3.0×48 3 48 3.5 25.6-29.3 0.6-3.48 100 237 φ3.0×60 3 60 3.5 12.3-14.1 0.3-2 100 310 φ3.2×50 3.2 50 4 40.5-42 0.6-3 125 278

There are some other products you may be intersted in , please click to know about the details.

Carbonization furnace Shisha charcoal briquette machinery Charcoal/coal briquette machine Briquette Machine Hydraulic Briquette Machine Pellet Briquette Machine Sawdust Briquette Machine Rotary DryerSend your message to us. We'll respond as soom as possible.

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

.jpg)

(※ Click this button to inquiry)

(※ Click this button to inquiry)