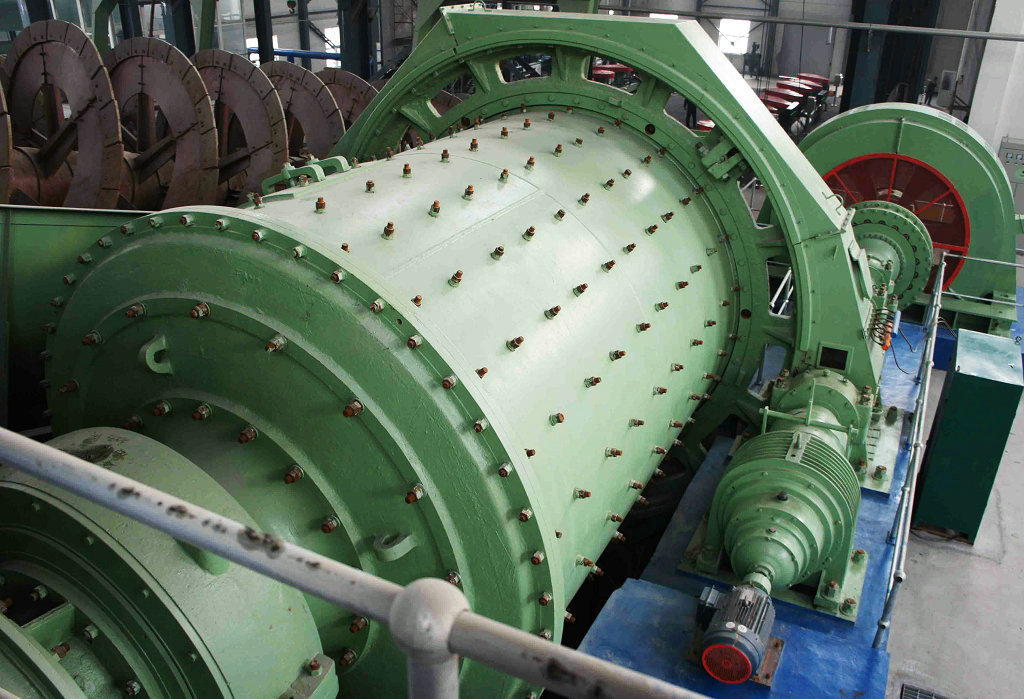

Cement Ball Mill

- Feed Size: 0-25mm

- Capacity: 5-60t/h

- Raw materials: Raw martial of cement factory

- Application: cement factory or mine industries as metallurgy

Cement Ball Mill is cement factory equipment, it is mainly used to grind end product and raw martial of cement factory. Cement Ball Mill also can apply on mine industries as metallurgy, chemical industry and electricity. It can use Cement Ball Mill to grind all kinds of ores, cement clinker and the other grind ability materials.

Features of Cement Ball Mill

1. Cement Ball Mill has high adaptability, it can produce cautiously, big crushing ratio and easy to adjust the fineness of powder product.

2. Cement Ball Mill can not only produce in wet way, but also can grind and dry at the same time.

3. Portland Cement Mill has high grinding efficiency, big output, low power cost. Especially when grinding slag cement, the end product temperature can decrease 20-40℃, and the product fineness is easy to adjust.

4. The system device and technological process of high fineness and high productive Cement Mill is easy, low investment and less factory building area.

Cement Ball Mill Working Principle:

Material enters spirally and evenly the first warehouse of the milling machine along the input material hollow axis by input material device. In this warehouse, there is a ladder scale board or ripple scale board, and different specification steel balls are installed on the scale board.When the barrel body rotates cement ball mill produces centrifugal force, at the same time, the steel ball is carried to some height and falls to make the material grinding and striking.

After grinded coarsely in the first warehouse, the material then enters into the second warehouse for regrinding with the steel ball and scale board. In the end, the powder is discharged by output material board and the end products are completed.

Technical Parameter of Cement Ball Mill

|

Type(m)

|

Transmission form

|

Reducer

|

Power (kw)

|

Capacity (t/h)

|

Weight (t)

|

|

|

Type

|

speed ratio

|

|||||

|

φ1.83×7

|

Edge

|

ZD60

|

4.5

|

245

|

6.5-8

|

36

|

|

φ2.2×7.5

|

Edge

|

ZD70

|

5

|

380

|

8-10

|

56

|

|

φ2.2×11

|

Center

|

D110

|

35.5

|

630

|

12-13

|

104.6

|

|

φ2.2×13

|

Center

|

D110

|

35.5

|

630

|

16-18

|

114

|

|

φ2.4×13

|

Center

|

D110

|

35.5

|

800

|

20-23

|

171.5

|

|

φ2.6×13

|

Center

|

MFY100

|

19.5

|

1000

|

28-32

|

149.7

|

|

φ3×9

|

Edge

|

D125

|

41.2

|

1000

|

28-36.5

|

136.4

|

|

φ3×11

|

Center

|

D140

|

42.8

|

1250

|

36-47

|

180

|

|

φ3.2×13

|

Center

|

D140

|

36.5

|

1600

|

45-50

|

198

|

|

φ3.8×13

|

Center

|

MFY250

|

16.5

|

2500

|

60-62

|

204

|

There are some other products you may be intersted in , please click to know about the details.

Carbonization furnace Shisha charcoal briquette machinery Charcoal/coal briquette machine Briquette Machine Hydraulic Briquette Machine Pellet Briquette Machine Sawdust Briquette Machine Rotary DryerSend your message to us. We'll respond as soom as possible.

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

.jpg)

(※ Click this button to inquiry)

(※ Click this button to inquiry)