Stone Production Line

- Feed Size: 0-1020mm

- Capacity: 1-800t/h

- Raw materials: Stone

- Application: Sand making line, stone making line

1. High degree of automatic operation; the entire production line requires almost no manual operation except for machine starting and stopping, routine maintenance.

2. High productivity, low investment, and good appreciation.

3. Regular end product granularity, good grain shape, and low powder output.

4. Adopting high advanced control system to ensure security and reliable operation of the entire production line.

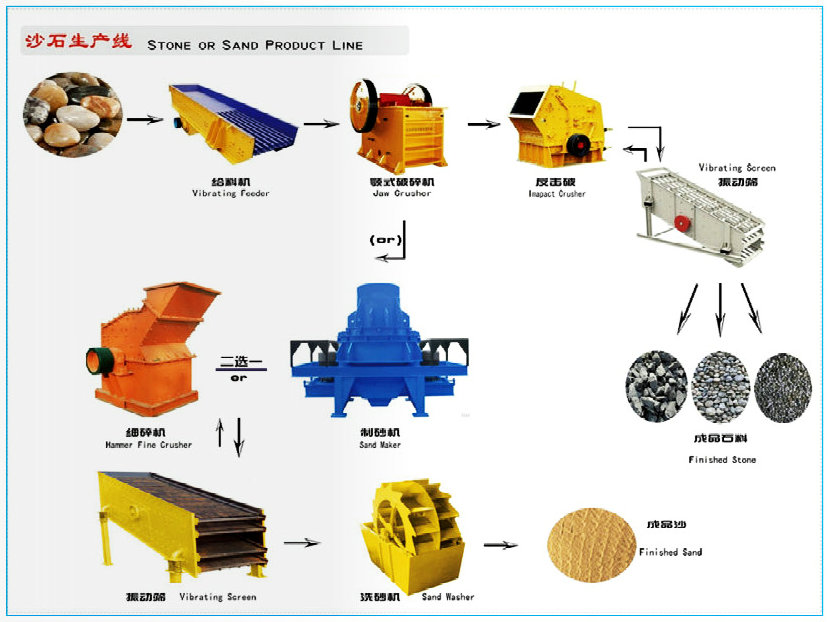

Large stone materials from the hopper fed into jaw crusher through vibrating feeder for primary crushing evenly and continuously; the crushed materials are transported to impact crusher or sand making machine for fine crushing through belt conveyor; then the materials are transported to vibrating screen to be separated into different sizes. The end products with desired sizes will be transported to the final product pile and those with big sizes will return to impact crusher or sand making machine for re-crushing. This forms closed and continuously automatic cycles. The plant can be equipped with dust removing facilities to protect environment according to customers' requests.

There are some other products you may be intersted in , please click to know about the details.

Carbonization furnace Shisha charcoal briquette machinery Charcoal/coal briquette machine Briquette Machine Hydraulic Briquette Machine Pellet Briquette Machine Sawdust Briquette Machine Rotary DryerSend your message to us. We'll respond as soom as possible.

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761  (※ Click this button to inquiry)

(※ Click this button to inquiry)