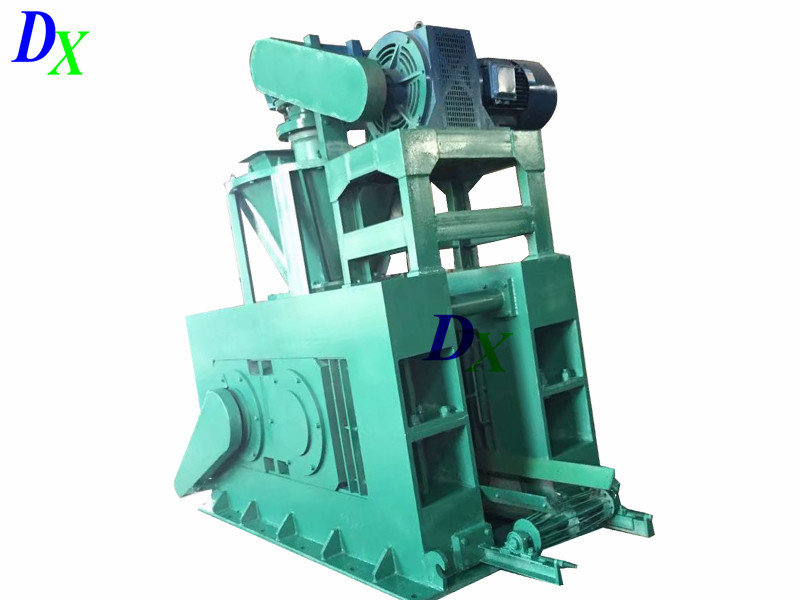

Hydraulic Briquette Machine

- Feed Size: 1-3mm

- Capacity: 0.5-15t/h

- Raw materials: Such as dedusting ash, pool mud, oxide, slag, iron flavor powder, aluminum ash powder, silicon manganese ore powder, etc.

- Application: he ball and brick making of non-ferrous metal and ferrous metal mineral powder, it enters the furnace directly to increase the additional value.

High Pressure Ball Briquette Machine also named dry power briquette machine. The High Pressure Ball Machine mainly applies on the ball and brick making of non-ferrous metal and ferrous metal mineral powder, it enters the furnace directly to increase the additional value. All metallurgy industry waste and accessory that need furnace use ball press machine. Such as dedusting ash, pool mud, oxide, slag, iron flavor powder, aluminum ash powder, silicon manganese ore powder, etc.

Advantage of the Hydraulic briquette Machine

1. High Briquetting Pressure

2. Adjustable main engine revolution

3. Equip with spiral feeding equipment

Application

Hydraulic Briquette Machine also named dry power briquette machine. The Hydraulic Briquette Machine mainly applies on the ball making of non-ferrous metal and ferrous metal mineral powder, it enters the furnace directly to increase the additional value. All metallurgy industry waste and accessory that need furnace use ball briquetting machine. Such as dedusting ash, pool mud, oxide, slag, iron flavor powder, aluminum ash powder, silicon manganese ore powder, etc. Pressed powder materials into a ball to reduce dust and facilitate transport. Such as iron powder, charcoal, clay, coke breeze, coal, lime powder, etc.

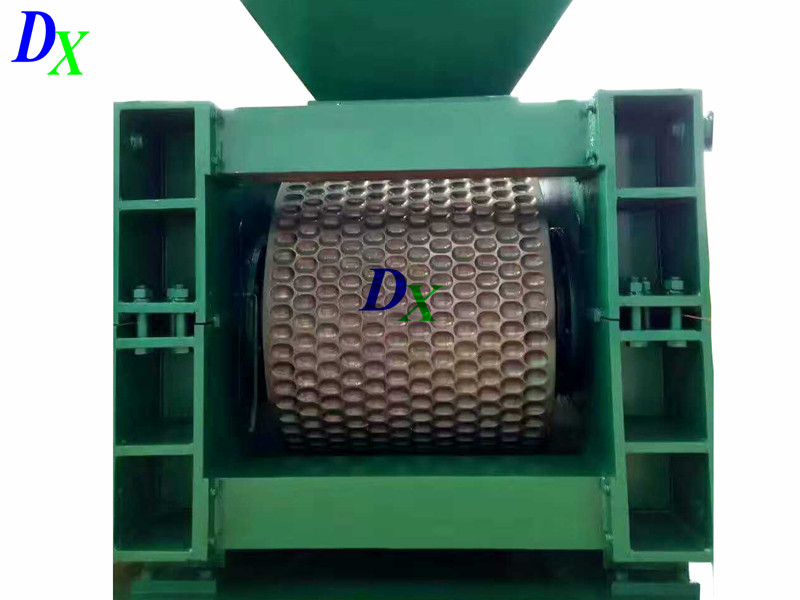

Requirements for materials

1. Material size about 80 to 200 mesh.

2. Materials are not allowed has hard metal objects to avoid damaging the pressure roller.

3. Return materials should not have too much clumps(3mm), return materials is not more than 50%

in the feeding materials.

4. Supply of materials must be sufficient, use variable speed screw feeder is better.

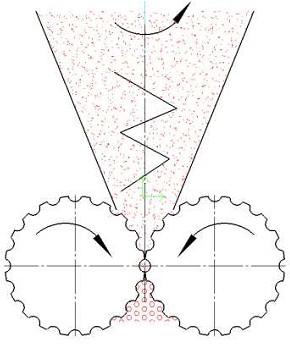

Working Principle of Hydraulic briquette Machine

Hydraulic briquette Machine will pass the power on to the two pressure roller through the reducer. The two sides and roll rotation, in both the rotating roll, Natural materials to enter the ball roll mode, with the roll rotation, material pressure on a small become larger, when the material to the two rollers rotating line contact point, the pressure of materials has reached the peak. Tremendous pressure in the role of line, the materials becomes a finished product from the powder ball.

Hydraulic Dry Powder briquette Machine

Type Diameter(mm) Roller Width(mm) Power(kw) Yield(kg/h) LYQ 0.5

φ299

180

18.5

500

LYQ 1.0

φ367

183

37

1000

LYQ 1.5

φ367

183

45

1500

LYQ 2.0

φ399.5

252

45

2000

LYQ 3.0

φ522

196

55

3000

LYQ 5.0

φ700-738

210/225

75

5000

LYQ 6.0

φ738

225

90

6000

LYQ 8.0

φ758

225

110

8000

LYQ 10

φ858

300

110

10000

There are some other products you may be intersted in , please click to know about the details.

Carbonization furnace Shisha charcoal briquette machinery Charcoal/coal briquette machine Briquette Machine Hydraulic Briquette Machine Pellet Briquette Machine Sawdust Briquette Machine Rotary DryerSend your message to us. We'll respond as soom as possible.

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

.jpg)

(※ Click this button to inquiry)

(※ Click this button to inquiry)