Jaw Crusher

- Feed Size: 20-1020mm

- Capacity: 1-650t/h

- Raw materials: Limestone, shale, basalt, river gravel, stone, iron ore, copper, steel slag, etc.

- Application: mining, smelting, building material, highway, railway, water conservancy and chemical industry

Jaw Crusher (also known as tiger mouth) appeared in 1858. Jaw crusher widely used in mining, smelting, building material, highway, railway, water conservancy and chemical industry and many other sectors, broken less than 320 MPa compressive strength of various materials.

Advantages of Jaw Crusher

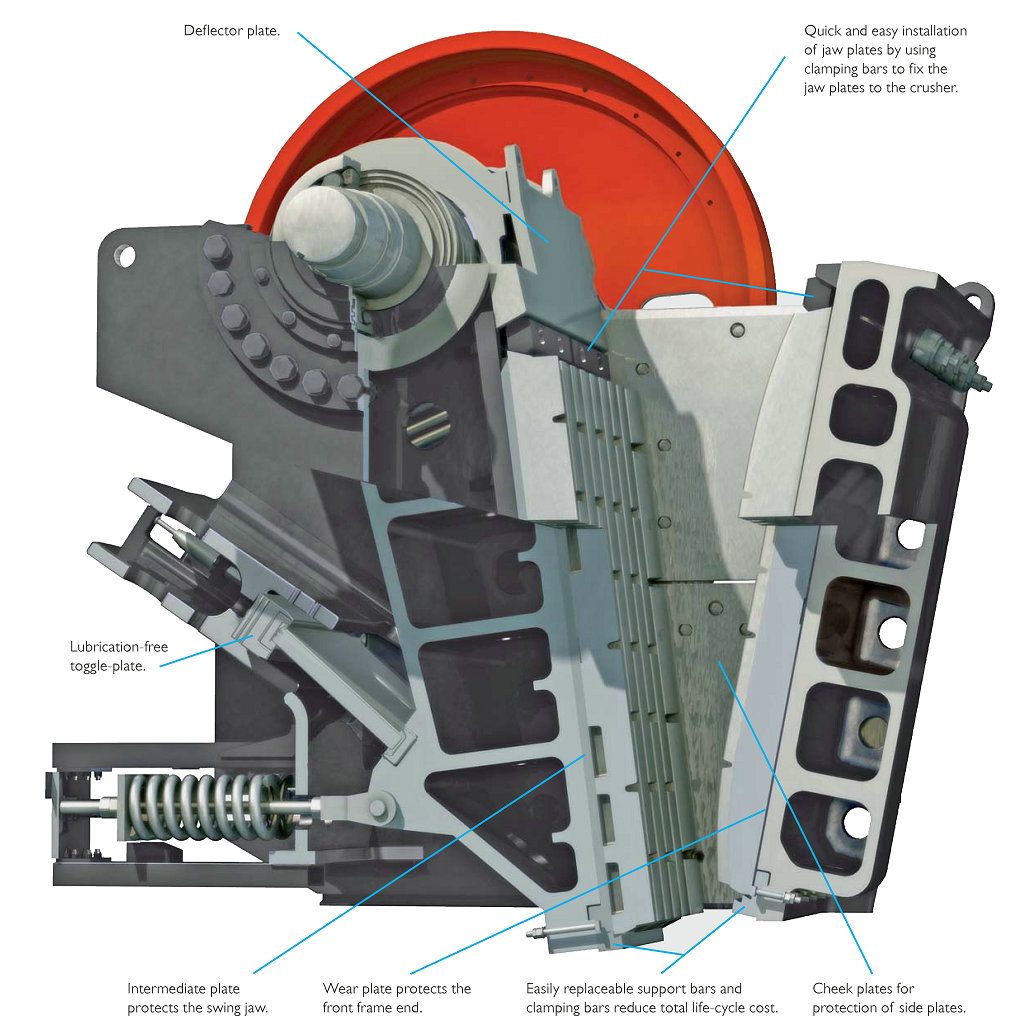

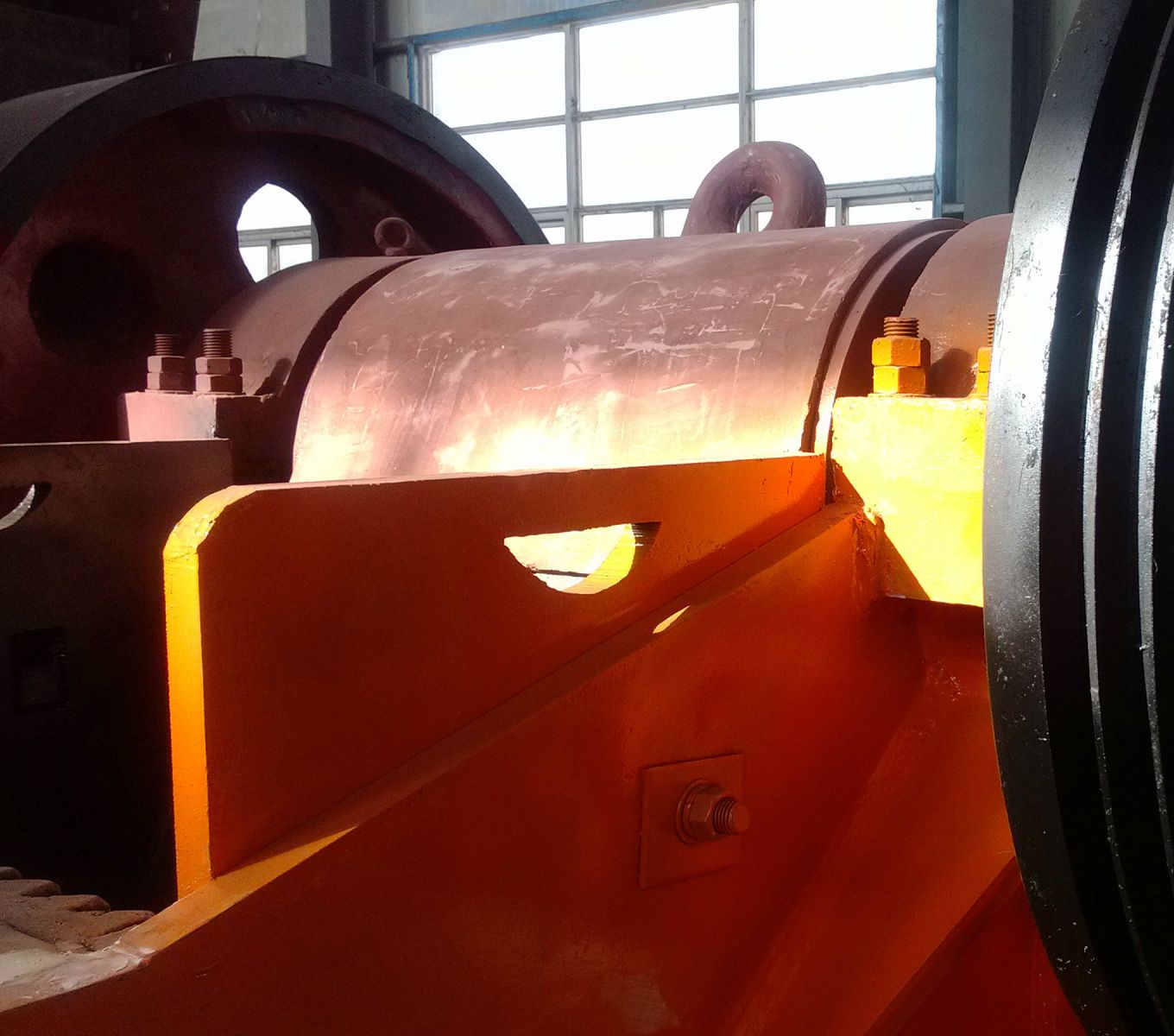

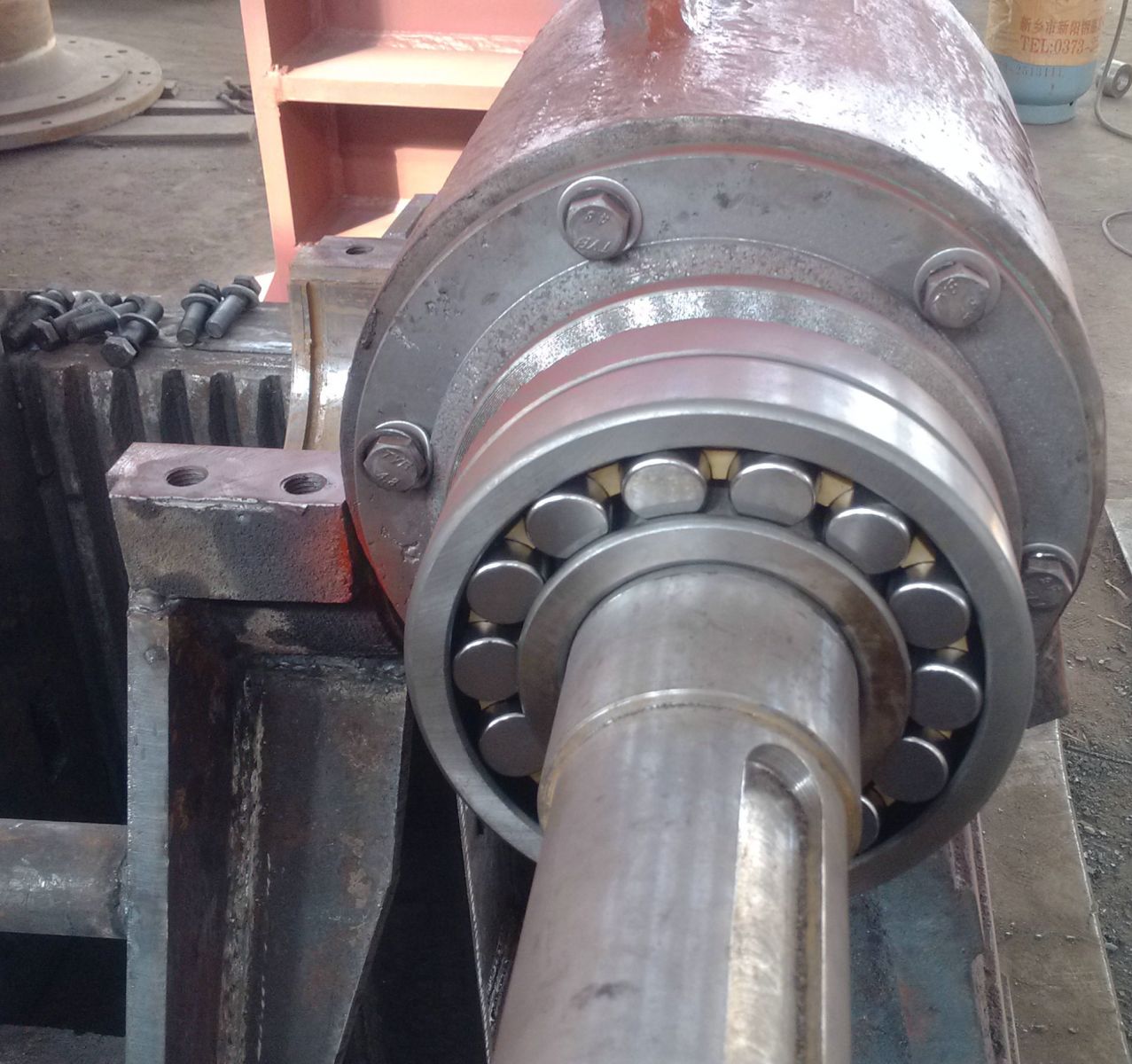

1. Heightened movable jaw assembly causes it to be more long-lasting. Movable jaw assembly adopts a high-quality steel casting, and moves through two large cast steel flywheel drive. Additionally, heavy eccentric shaft has also adopted forging billet for processing. All those increase the risk for PE jaw crushers with exceptional reliability.

2. Integrated Cast Steel Structure Adopted in Axle Bearing housing. Integrated cast steel structured axle bearing housing can guarantee being perfectly cooperating with the crushing frame.

3.Quicker and convenient adjustment on the discharging opening. Main structure adopted within the crushing cavity helps make the actual feed mouth width add up to the set width of the feeding opening.

Working principle of Jaw Crusher

The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves. So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet.

Main Specifications of Jaw Crusher

|

Type

|

Feed Inlet Size (mm)

|

Max. Feeding Size (mm)

|

Adjust range of discharge opening (mm)

|

Capacity

(t/h) |

Power (kw)

|

Weight

(t) |

Overall Size(L*W*H) (mm)

|

|

PE250×400

|

250×400

|

200

|

20-50

|

5-20

|

15

|

2.9

|

1430×1310×1340

|

|

PE400×600

|

400×600

|

350

|

40-100

|

15-60

|

30-37

|

6.8

|

1700×1732×1653

|

|

PE500×750

|

500×750

|

425

|

50-100

|

40-100

|

45-55

|

11.2

|

2035×1921×2000

|

|

PE600×900

|

600×900

|

480

|

65-160

|

60-140

|

55-75

|

16.5

|

2290×2206×2370

|

|

PE750×1060

|

750×1060

|

630

|

80-150

|

80-230

|

90-110

|

29

|

2655×2302×3110

|

|

PE900×1200

|

900×1200

|

750

|

95-165

|

140-320

|

110-132

|

54.5

|

3789×3050×3025

|

|

PE1000×1200

|

1000×1200

|

850

|

105-185

|

180-400

|

160-200

|

56.5

|

3900×3320×3280

|

|

PE1200×1500

|

1200×1500

|

1020

|

150-300

|

250-650

|

220-250

|

99.6

|

4300×3540×4043

|

|

PEX150×250

|

150×250

|

125

|

10-40

|

1-3

|

5.5

|

0.85

|

896×745×935

|

|

PEX150×750

|

150×750

|

125

|

12-45

|

5-16

|

15

|

3.8

|

1205×1495×1203

|

|

PEX250×750

|

250×750

|

210

|

25-60

|

10-40

|

22-30

|

5

|

1667×1545×1020

|

|

PEX250×1000

|

250×1000

|

210

|

25-60

|

15-50

|

30-37

|

6.8

|

1964×1550×1380

|

|

PEX250×1200

|

250×1200

|

210

|

25-60

|

20-60

|

37-45

|

8.5

|

2192×1605×1415

|

|

PEX300×1300

|

300×1300

|

250

|

20-90

|

30-90

|

55-75

|

12.5

|

2200×2200×1960

|

|

PEX400×1300

|

400×1300

|

300

|

35-95

|

40-100

|

75

|

11.7

|

2256×2100×1960

|

There are some other products you may be intersted in , please click to know about the details.

Carbonization furnace Shisha charcoal briquette machinery Charcoal/coal briquette machine Briquette Machine Hydraulic Briquette Machine Pellet Briquette Machine Sawdust Briquette Machine Rotary DryerSend your message to us. We'll respond as soom as possible.

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

(※ Click this button to inquiry)

(※ Click this button to inquiry)