-

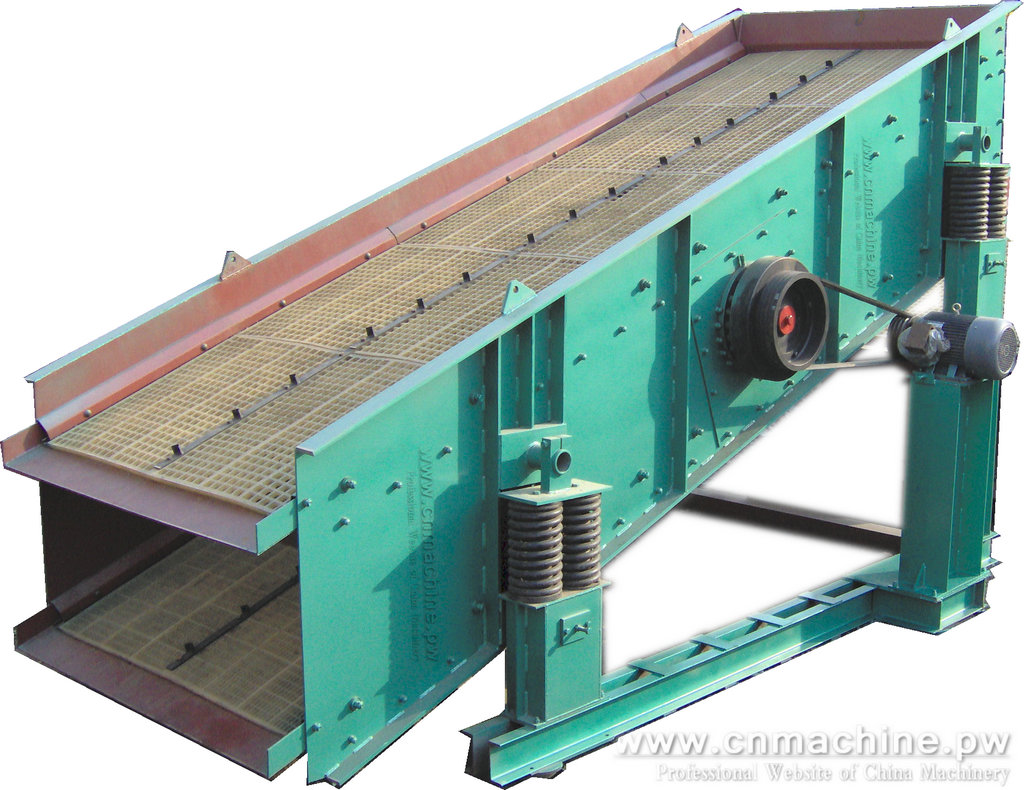

Vibrating screen is the circular vibrating type we called it circular vibrating screen also. Vibrating screens are widely used for grading and screening materials in such fields as chemical industry, minerals, quarry, building materials, water conservancy and hydropower, transportation, smelting and so on. Vibrating screens are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc. There are 40 specifications for this series vibrating screen, of which the heavy duty type of vibrating screens are for the classification of large size materials, while the light duty type of vibrating screens are for the middle and small size materials. This series circular vibrating screen is seat installation. Screen surface angle can be adjusted by changing the height of spring bearing position to achieve.

-

Screw Conveyor is mainly used for conveying powdery, granular and small piece of material, such as coal, carbon black, soda ash, reclaimed rubber powder, zinc oxide, calcium carbonate and small coal. It is not suitable for conveying perishable, viscous and easy to agglomerate material.

Screw conveyor suitable environment temperature is -20℃-50℃.material temperature should be less than 200℃,dip angle≤20°,conveying length general is less than 40 meters.The longest do not exceed 70 meters. -

The bucket elevator is one of lifting equipments frequently used in the industrial production. The most common is the belt-type bucket elevators and chain-type bucket elevator.

TD-belt bucket elevator to meet the general use. Chain-type bucket elevator is used in a wider range of materials. Widely used in metallurgical, chemical, building materials, mining, grain and oil, food, feed, plastics, pharmaceutical and other industries. -

Belt conveyor have large conveying capacity, simple structure, convenient maintenance, low cost, highly optimized for general use etc. Widely used in mining, metallurgy, coal, transport, hydropower and other departments for conveying bulk material or formed articles. According to the requirements of the transportation process, it can be single conveyor, also can be many sets of combination or combined with other conveyor, turn into a horizontal or inclined conveying system. Work environment is generally -25℃-40℃,special environment, should adopt the corresponding protection measures. Conveying density is 500-2500kg/ m³ of various materials.

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

.jpg)