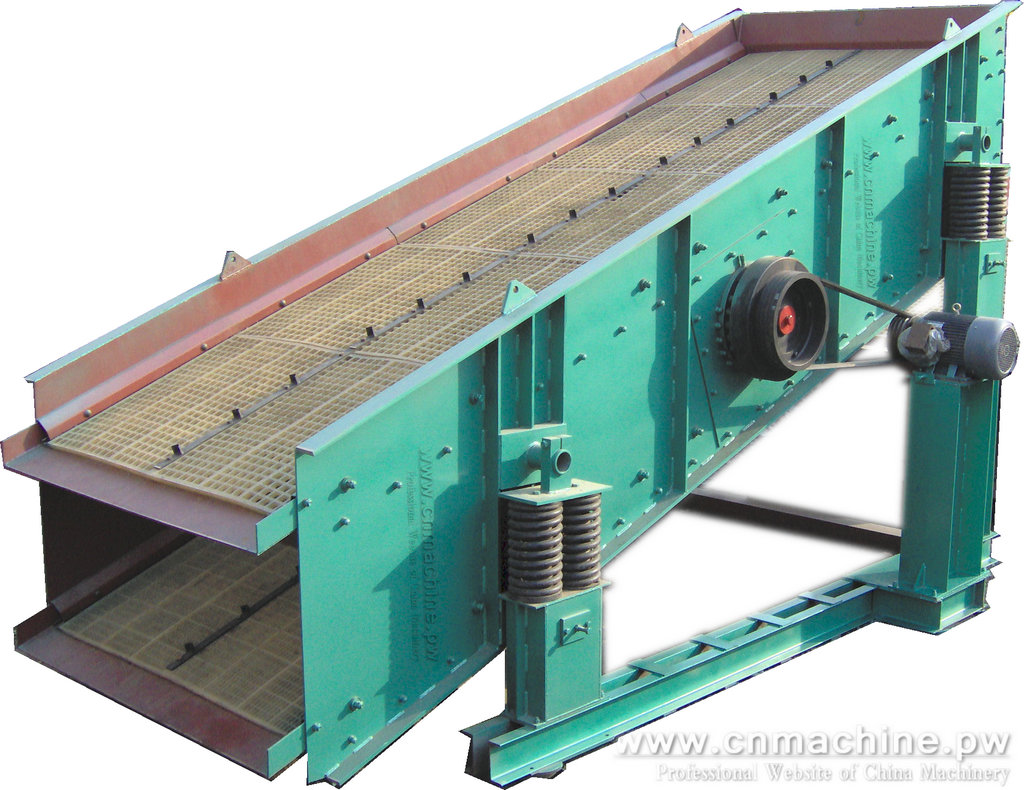

Vibrating Screen

- Feed Size: 3-150mm

- Capacity: 10-800t/h

- Raw materials: coal, minerals, coke etc

- Application: chemical industry, minerals, quarry, building materials, water conservancy and hydropower, transportation, smelting

Vibrating screen is the circular vibrating type we called it circular vibrating screen also. Vibrating screens are widely used for grading and screening materials in such fields as chemical industry, minerals, quarry, building materials, water conservancy and hydropower, transportation, smelting and so on. Vibrating screens are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc. There are 40 specifications for this series vibrating screen, of which the heavy duty type of vibrating screens are for the classification of large size materials, while the light duty type of vibrating screens are for the middle and small size materials. This series circular vibrating screen is seat installation. Screen surface angle can be adjusted by changing the height of spring bearing position to achieve.

Advantages of Vibrating Screen:

1. Low overall height owing to the horizontal arrangement of assemblies

2. Optionally with bottom or top drive unit

3. Optimum adaptation to the particular screening job by changing the angle of throw

4. This series of vibrating screens use eccentric block to produce strong exciting force.

Working Principle of Vibrating Screen

Vibrating screen moves round. It has multi-layers and is of high efficiency. The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line. In screen grading, the material is separated mechanically on screen plates. Rolling bearings in vibrating screens are stressed by high, mostly shock-type loads. Moreover, the bearings, while rotating about their own axis, perform a circular, elliptical or linear vibrating motion.

Techical Parameter of Vibrating Screen

|

Type |

Sieve Specification

|

Sieve Layer

|

Mesh Size

|

Feeding Size

|

Capacity

|

Power

|

Weight

|

Dimensions (mm)

|

|

2YZS1237

|

3700×1200(mm)

|

2

|

3-50(mm)

|

≤200(mm)

|

10-80(t/h)

|

11kw

|

2.40t

|

4773×2050×2247

|

|

3YZS1237

|

3700×1200(mm)

|

3

|

3-50(mm)

|

≤200(mm)

|

10-80(t/h)

|

11 kw

|

3.05 t

|

4773×2050×2700

|

|

2YZS1548

|

4800×1500(mm)

|

2

|

3-100(mm)

|

≤400(mm)

|

30-200(t/h)

|

15 kw

|

5.35 t

|

5900×2270×1620

|

|

3YZS1548

|

4800×1500(mm)

|

3

|

3-100(mm)

|

≤400(mm)

|

30-200(t/h)

|

15 kw

|

6.07 t

|

5900×2270×1670

|

|

2YZS1848

|

4800×1800(mm)

|

2

|

3-100(mm)

|

≤400(mm)

|

50-280(t/h)

|

18.5kw

|

6.15 t

|

5900×2560×1620

|

|

3YZS1848

|

4800×1800(mm)

|

3

|

3-100(mm)

|

≤400(mm)

|

50-280(t/h)

|

18.5 kw

|

6.93 t

|

5900×2560×1670

|

|

2YZS1860

|

6000×1800(mm)

|

2

|

3-100(mm)

|

≤400(mm)

|

65-550(t/h)

|

22 kw

|

6.95 t

|

7060×2560×1620

|

|

3YZS1860

|

6000×1800(mm)

|

3

|

3-100(mm)

|

≤400(mm)

|

65-550(t/h)

|

22 kw

|

7.70 t

|

7060×2560×1670

|

|

4YZS1860

|

6000×1800(mm)

|

4

|

3-100(mm)

|

≤400(mm)

|

65-550(t/h)

|

30 kw

|

8.70 t

|

7060×2560×1930

|

|

2YZS2160

|

6000×2100(mm)

|

2

|

3-100(mm)

|

≤400(mm)

|

81-720(t/h)

|

22 kw

|

8.48 t

|

7130×2990×1760

|

|

3YZS2160

|

6000×2100(mm)

|

3

|

3-100(mm)

|

≤400(mm)

|

81-720(t/h)

|

30 kw

|

9.24 t

|

7130×2990×1810

|

|

4YZS2160

|

6000×2100(mm)

|

4

|

3-100(mm)

|

≤400(mm)

|

81-720(t/h)

|

30 kw

|

10.45 t

|

7130×2990×1930

|

|

2YZS2460

|

6000×2400(mm)

|

2

|

3-150(mm)

|

≤400(mm)

|

100-810(t/h)

|

30 kw

|

12.35 t

|

7130×4121×1810

|

|

3YZS2460

|

6000×2400(mm)

|

3

|

3-150(mm)

|

≤400(mm)

|

100-810(t/h)

|

37 kw

|

13.85 t

|

7130×4121×1940

|

|

4YZS2460

|

6000×2400(mm)

|

4

|

3-150(mm)

|

≤400(mm)

|

100-810(t/h)

|

37 kw

|

15.60 t

|

7130×4121×2080

|

There are some other products you may be intersted in , please click to know about the details.

Carbonization furnace Shisha charcoal briquette machinery Charcoal/coal briquette machine Briquette Machine Hydraulic Briquette Machine Pellet Briquette Machine Sawdust Briquette Machine Rotary DryerSend your message to us. We'll respond as soom as possible.

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

(※ Click this button to inquiry)

(※ Click this button to inquiry)