45TPH Coal Briquetting Production Line

45TPH Coal Briquettes Production Line

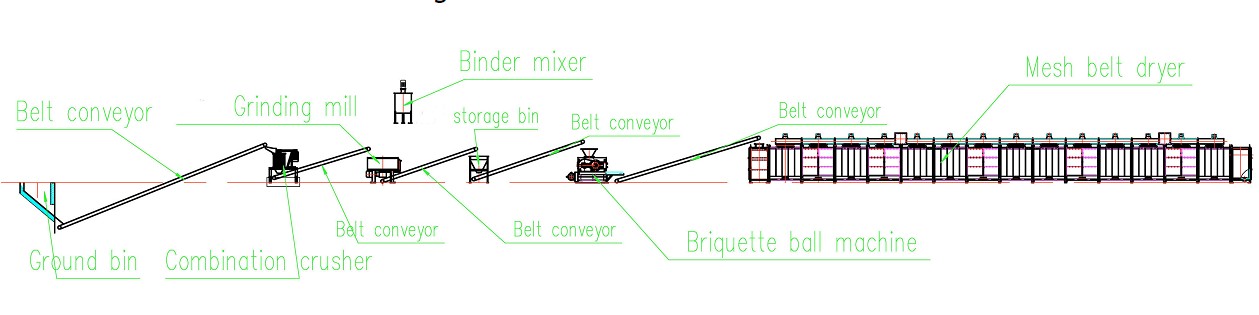

The Design Process

1. Raw coal in the stockyard delivered to the hopper by Forklift machines, Here, if the raw coal contains more impurities, it need install a vibrating screen for sieving, then to crusher crushing to coal powder( ≤5mm),that ensure uniform material particles.

2. Broken coal powder into batching machine to Double Shaft Mixer. At the same time,Mixing Drum mixed dry powder binder and water then also to Double Shaft Mixer. The Double Shaft Mixer make the adhesives and coal powder are well mixed、fitting、homogenization.

3. Then the Mixed material is transferred by Dosing Machine to Coal Ball Briquetting machine. The Ball output will enter the dryer for drying and completion of the production

Equipment list:

|

No. |

Equipment Name |

Type |

Capacity (t/h) |

Power (Kw) |

Remark |

|

1 |

Silo |

Provides design, user can self-provide |

|||

|

2 |

Vertical Shaft Hammer Crusher |

PCL-1250Ⅲ |

45 |

90 |

Coal particle size to meet the requirements, can not equipped |

|

3 |

Double Shaft Mixer |

JB-4000 |

45 |

45 |

|

|

4 |

Bin Mixer |

XB-1200 |

— |

3 |

|

|

5 |

Storage Bin |

Provides design, user can self-provide |

|||

|

6 |

Briquette Machine |

YHQ-45 |

45 |

132 |

Roll Diameter(mm)1200 |

|

7 |

Mesh Belt Dryer |

WD |

25 |

15kw |

|

|

8 |

Belt Conveyer |

TD-B500 |

30-120 |

Length and power is determined according to the site |

|

Contact: Alakay

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

.jpg)