How briquette machine works?

How briquette machine works?

1.

The machine can press all kinds of mineral powder, metal powder, coal powder, coke powder and other materials into certain form. Because of the forced squeeze by pair roller, the products have high density, high hardness. The press roller of the machine uses 65Mn rigid material with good abrasion resistance, lengthening effectively service life of the press roller.

2. Working principle

The series of briquetting machine transmit on power to the pair rollers through reducer, and make the pair roller drive in opposite direction. The materials naturally fall into the roller cavity. With the driving of the two rollers, the pressure of materials improves from small t big. When materials go to the rollers rotating line connecting point, the pressure of the two rollers reaches the peak pressure. These materials become finished briquettes from powder the huge line pressure.

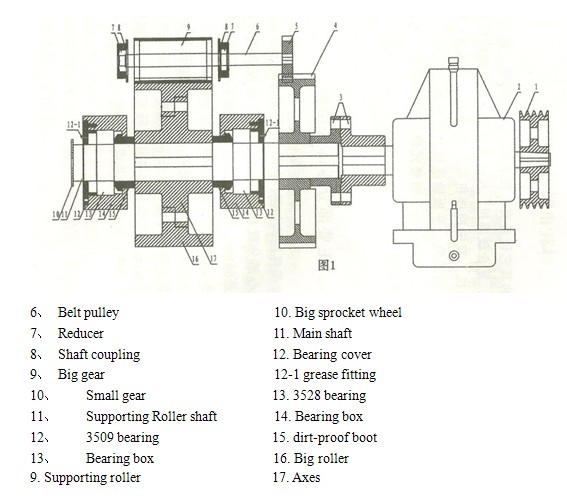

3. Main parts

The major parts of the components shown in figure 1, there are still the core part of the briquetting machine, which is the roller. It depends on its quality of the roller's life. The roller's material is 65Mn and it divide into two kinds, one is whole casting, and the other is forging according to forming method. The density is small and the structure is rough, but economic. Casting is formed by air hammer heavy, which improve the density and wear resistance, so that it extends the service life of the roller. The cavity of the roller has good flow chart. This kind of roller fit for all kinds of materials. It fits for metal powder materials, but the disadvantage is a little expensive cost.

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

.jpg)