-

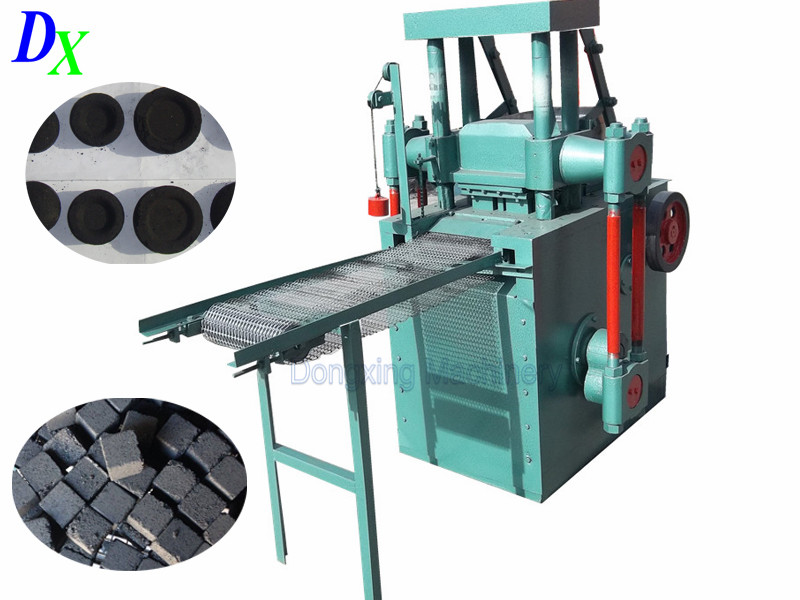

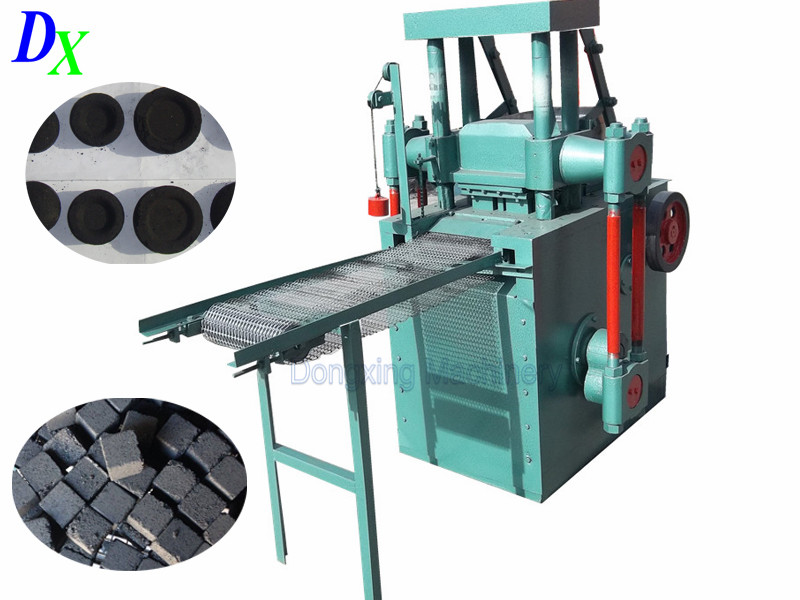

This machine is very popular in Arab countries and southeast countries. It is applicable for making small tablets, cylinder shape and cuboic shape from coal and charcoal dust. The output briquette in good density, perfect shape and good appearance.

-

This machine can make charcoal stick with hole or without hole. Solid or hollow shape. This charcoal stick can be used as fuel, BBQ and so on. On the other hand, this machine can press coal / charcoal powder into briquettes, and can be formed in different shapes with different molds.

-

Briquette Machine can used to press various powders such as coal powder, iron powder, coking coal, slag, oxidation iron sheet, carbon dust, gypsum, tailings, sludge, kaolin, active carbon and burnt powder, etc. Mineral Powder Ball Press Machine applies on the industries such as refractory material, electric powder plant, metallurgy, chemical industry, energy, transportation and heating, etc.

-

Hydraulic briquettie Machine also named dry power briquette machine. The High Pressure Ball Machine mainly applies on the ball and brick making of non-ferrous metal and ferrous metal mineral powder, it enters the furnace directly to increase the additional value. All metallurgy industry waste and accessory that need furnace use ball press machine. Such as dedusting ash, pool mud, oxide, slag, iron flavor powder, aluminum ash powder, silicon manganese ore powder, etc.

-

This side of the ring die pellet machine can process waste such as sawdust, straw, rice husk, bark and other biomass. To briquetting of the particles for high-density fuel,it is the ideal alternative to kerosene fuel, both to conserve energy and reducing emissions, with good economic and social benefits.

-

Sawdust Briquette Machine is the equipment use in mechanism charcoal production line, straw rod production line, biomass briquette production line.

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

.jpg)

.jpg)

.jpg)